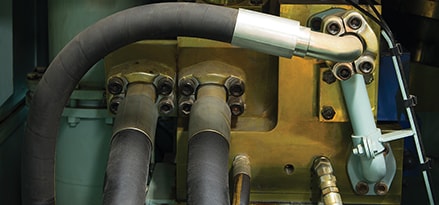

Mobil SHC™ 500 Series hydraulic oils

Our Mobil SHC 500 Series synthetic hydraulic oils are designed to provide excellent wear protection for high-pressure vane, piston and gear pumps operating in a wide range of temperatures. They are formulated to provide outstanding low- and high-temperature performance and equipment protection up to three times longer than comparable conventional products.

Mobil SHC 500 Series hydraulic oils can help reduce energy consumption by up to 6.2 per cent compared to conventional hydraulic oils*. They can also help:

- Extend filter life

- Improve hydraulic system efficiency

- Increase system cleanliness and durability

- Decrease machine maintenance

- Extend oil drain intervals

*Results are based on controlled laboratory tests and may vary depending on equipment type and condition and operating conditions.

Product Information

The Mobil SHC 500 Series hydraulic oils exhibit outstanding low and high temperature performance helping to provide an extra margin of equipment protection above and beyond the capabilities of comparable mineral oil-based products. Their excellent oxidation resistance allows extension of oil and filter change intervals while assuring exceptionally clean systems and trouble-free operation. Their high level of anti-wear properties and excellent film strength characteristics result in exceptional equipment performance that helps prevent unplanned equipment breakdowns, and maximize equipment uptime, which can enable potential improvements in production capacity. Their controlled demulsibility permits the oils to work well in systems contaminated with small amounts of water yet readily separate large amounts of water.