Exxon Aviation Oil Elite™ 20W-50

Exxon Aviation Oil Elite™ 20W-50 is a premium quality, semi-synthetic, ashless-dispersant aviation piston engine oil. It is formulated from select, highly refined mineral base oils, a polyalphaolefin synthetic base oil, and ashless performance additives providing outstanding engine cleanliness, wear protection, and corrosion protection.

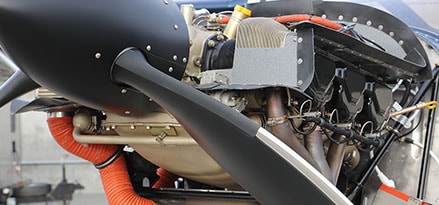

Exxon Aviation Oil Elite 20W-50 is designed to satisfy all opposed piston engine manufacturers’ requirements under a wide range of climatic conditions. It provides:

- Excellent engine cleanliness

- Outstanding protection against wear, rust and corrosion

- Better cold-start protection and a stronger lubricant film in typical operating temperatures, compared to mono-grade oil

- Compatibility with all commercial aviation piston-engine oils

Product information

Data sheets

Controlling rust and wear in piston engines

This tech topic explores different types of lubricants, how they protect piston engines and the role they play in extending engine life.

Learn moreTechnical Resources

Teledyne Continental

Textron Lycoming

- Wear protection

- Corrosion protection

- Rust protection

- Severe operating conditions

- High/Low temperature viscosity

- Ashless

- MIL-L-22851D/SAE J1899

- Teledyne Continental Motors (MHS 24)

- Textron Lycoming Spec No 301F